Cross Docking Meaning

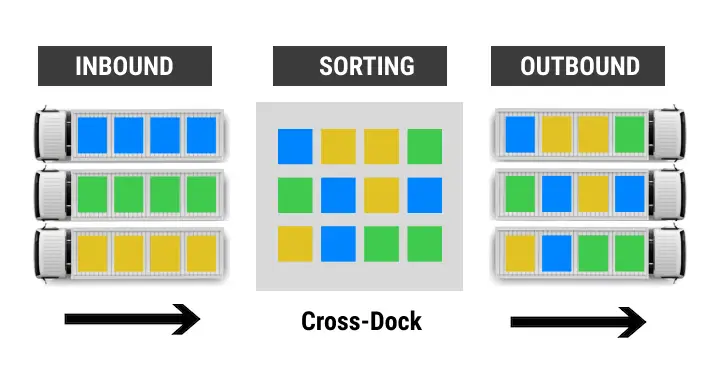

Cross docking is a logistics strategy that bypasses traditional warehousing. Products are received from suppliers, then immediately sorted and directed towards outbound transportation for delivery to customers. There’s minimal to no storage time in between. Think of it as a distribution hub where goods are constantly on the move.

A cross-docking facility acts as a high-speed sorting center. Products are received, sorted based on their final destinations, and immediately loaded onto outbound vehicles for shipment. Ideally, the entire process occurs within 24 hours, keeping products constantly moving through the supply chain.

Example:

Visualize you run a toy store chain with multiple locations. Every week, you receive shipments of toys from different toy manufacturers. Instead of storing these toys in a warehouse and then sending them to individual stores, you decide to use cross-docking.

With cross-docking, as soon as the toy shipments arrive, they are quickly unloaded and sorted at a special facility. Toys for each store are immediately loaded onto trucks designated for that store. There is no need for storage in the facility because the toys are directly transferred from the inbound trucks to the outbound trucks.

Once the trucks are loaded, they drive directly to the respective stores and unload the toys. This way, the toys go straight from the manufacturers to the stores without any storage time in between.

By using cross-docking, you can get the toys to your stores faster, save on storage costs, and ensure that the latest toys reach the shelves quickly. This benefits both your business and your customers, who can enjoy the newest toys without any delays.

Cross Docking in Supply Chain

Within the supply chain, cross docking eliminates unnecessary storage steps, accelerating product movement. Here’s a breakdown of the process:

- Inbound Shipment: Goods arrive from suppliers at a designated cross-docking facility.

- Sorting and Consolidation: Products are unloaded, meticulously sorted based on cross docking instructions (often customer orders or final destinations), and potentially consolidated with other items going to the same location.

- Outbound Shipment: Sorted products are directly loaded onto outbound trucks or other transportation modes for prompt delivery to customers.

Types of Cross Docking

There are two main types of cross-docking:

- Pre-distribution: Inbound goods are sorted and repacked based on pre-determined customer orders before being shipped out.

- Post-distribution: Large shipments are broken down into smaller quantities for individual deliveries upon arrival.

Cross Docking Examples

1. Industry leaders like Walmart and Amazon are known for their extensive use of cross docking. They strategically place cross-docking facilities near ports or transportation hubs to receive incoming shipments from suppliers worldwide. These facilities then sort and consolidate products for quick delivery to their vast network of stores or fulfillment centers.

2. Car manufacturers Toyota have long been champions of cross docking. Their just-in-time (JIT) manufacturing philosophy relies heavily on this strategy. Parts from various suppliers are delivered directly to assembly lines using cross docking, ensuring a steady flow of materials without the need for extensive warehousing.

Why cross-docking is required?

Reduced Inventory Costs:

Cross-docking helps minimize inventory holding costs by eliminating the need for long-term storage. Products are quickly transferred from inbound to outbound vehicles, reducing the need for warehousing space.

Improved Efficiency:

By bypassing storage and minimizing handling, cross-docking reduces order processing time, labor requirements, and the risk of errors or damage during storage.

Faster Order Fulfillment:

Cross-docking allows for rapid sorting and consolidating of products, enabling faster order processing and shipment. This strategy is particularly useful for time-sensitive products or those with high demand variability.

Cost Savings:

By eliminating or reducing storage needs and optimizing transportation routes, cross-docking can lead to cost savings in warehousing, inventory management, and transportation.

FAQs:

What types of products are suitable for cross-docking?

Cross-docking is most suitable for non-perishable items, standardized goods, and products with high demand variability, such as consumer electronics, apparel, or non-perishable food items.

What are the key challenges in implementing cross-docking?

Implementing cross-docking requires effective coordination between suppliers, carriers, and distribution centers, as well as reliable transportation networks and timely deliveries to ensure smooth transfer of products.

How does cross-docking differ from traditional warehousing?

Cross-docking eliminates or minimizes the need for long-term storage by directly transferring products from inbound to outbound vehicles, optimizing inventory levels, reducing handling, and streamlining order fulfillment processes.