Reverse Logistics Meaning

Reverse logistics refers to the process of managing the flow of products or materials from their final destination back to their point of origin in simple words back to the seller.

It involves handling returns, repairs, refurbishments, recycling, and the overall management of the reverse supply chain. Reverse logistics is particularly important in industries where products have a longer lifespan or where recycling and reusing materials are essential.

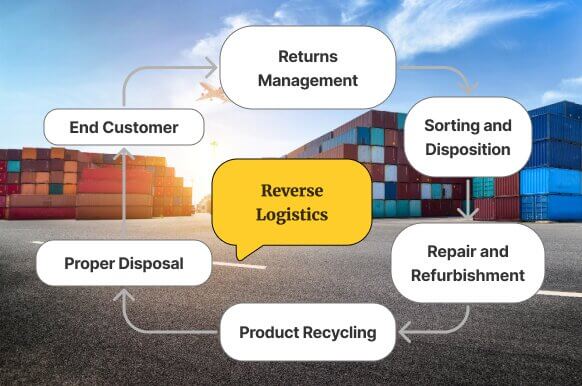

The Reverse Logistics Process

The reverse logistics process encompasses a series of activities that occur after the sale of a product, focusing on its post-consumption journey. This process can be divided into several stages:

Returns Management:

This stage involves receiving returned products from customers, inspecting them for defects or damages, and determining their disposition.

Sorting and Disposition:

In this stage, returned products are sorted based on their condition and potential for reuse, refurbishment, repair, recycling, or disposal.

Repair and Refurbishment:

If possible, returned products are repaired or refurbished to restore their functionality and aesthetic appeal, preparing them for resale or reuse.

Product Recycling:

Products that cannot be repaired or refurbished are sent for recycling, where valuable materials are extracted and reused in new products or processes.

Proper Disposal:

Products that are beyond repair or recycling are disposed of in an environmentally responsible manner, ensuring compliance with relevant regulations.

Achieving the Objectives of Effective Reverse Logistics

The primary goal of successful reverse logistics is to optimize the value recovery from returned products while minimizing waste and reducing environmental impact. By effectively managing the reverse supply chain, organizations can achieve the following objectives:

Cost Reduction:

Implementing efficient reverse logistics processes helps reduce costs associated with returns, repairs, and disposal, ultimately improving the overall profitability of the organization.

Customer Satisfaction:

By streamlining the returns process, addressing customer concerns promptly, and offering convenient options for returns or exchanges, companies can enhance customer satisfaction and loyalty.

Environmental Responsibility:

Reverse logistics enables proper disposal of products, reduces landfill waste, and promotes recycling, contributing to sustainable and environmentally responsible business practices.

Recovery of Value: Through repair, refurbishment, or recycling, organizations can recover value from returned products, either by reselling them at a lower price point or by reusing materials in new product manufacturing.

Supply Chain Efficiency:

Integrating reverse logistics into the overall supply chain improves visibility, enhances inventory management, and optimizes resource allocation, leading to a more efficient and responsive supply chain.

The Purpose of Utilizing Reverse Logistics

Reverse logistics is used by organizations for several reasons, including:

Customer Returns:

Reverse logistics addresses the need to handle customer returns efficiently and effectively, allowing organizations to provide seamless return experiences and maintain customer satisfaction.

Product Recovery:

Reverse logistics facilitates the recovery of value from returned products by repairing, refurbishing, or recycling them, reducing financial losses and maximizing resource utilization.

Compliance and Regulation:

Reverse logistics helps organizations adhere to environmental regulations and disposal requirements, ensuring proper handling of products that may contain hazardous materials.

Sustainability Initiatives:

Reverse logistics supports sustainability goals by promoting recycling, reducing waste, and minimizing the environmental impact of product disposal.

Quality Control and Improvement:

Analyzing returned products within the reverse logistics process provides valuable insights into product defects, customer feedback, and areas for improvement in design, manufacturing, or distribution.

In summary, reverse logistics is a crucial process that involves the management of product returns, repairs, refurbishments, recycling, and disposal. Its primary goal is to optimize value recovery while minimizing waste and environmental impact.

Reverse logistics is used to handle customer returns, recover value from returned products, comply with regulations, promote sustainability, and improve overall product quality and customer satisfaction.

Example:

Consider a scenario where you make an online purchase of a new smartphone, but upon its arrival, you realize that it’s not the exact model you had ordered. This disappointment leads you to contact the seller and request a return.

This is where reverse logistics plays a crucial role. The seller assists you by providing a return label, and you proceed to send the phone back to them. Upon receiving the phone, the seller carefully inspects its condition. If it’s found to be in good shape, they may choose to clean it and put it up for sale again.

In the event that any issues are identified, they may opt to send it for repairs or refurbishment. If the phone is determined to be irreparable, they will responsibly dispose of it or recycle its components. Reverse logistics ensures a seamless return process, maximizes the product’s value, and minimizes environmental impact.

FAQs:

- How does reverse logistics benefit companies?

Reverse logistics helps companies reduce costs, improve customer satisfaction, and recover value from returned products.

- What is the role of reverse logistics in sustainability?

Reverse logistics promotes sustainability by facilitating proper product disposal, reducing waste, and promoting recycling and reuse.

- How does reverse logistics contribute to supply chain efficiency?

Reverse logistics enhances supply chain efficiency by improving inventory management, optimizing resource allocation, and providing visibility into product returns and repairs.